Visiting Xingtu Super Smart Factory: Dare to show off your family’s wealth publicly

[Chexun. com] At the end of 2022, Starway Super Smart Factory, located in Jimo District, Qingdao, Shandong Province, is about to mass-produce a brand-new model of Starway brand — — Eta Ursae Majoris. When the new car was opened for blind ordering, Chexun. com visited the factory in person and made a field visit. I was deeply impressed by the intelligence, automation, networking, digital and environmental protection of the factory. I sincerely feel that it is impossible for any car company to dare to publicly show off its family property and let it visit. Only with strong strength can we have such confidence.

Star Road was born in 2019 and is a luxury brand owned by Chery. At present, Star Road TX, Zhuifeng, Lanyue, Lingyun and other models have been listed, and the sales volume has steadily increased. From January to November this year, the cumulative sales reached nearly 47,000 units, up 46% year-on-year. The price of bicycles rose from 139,000 yuan last year to 157,000 yuan this year, and it was sold in 8 countries in 2022. In Chile, Starway has been on an equal footing with Mercedes-Benz and BMW, collectively known as BBE.

At present, Starway has entered the development stage of 2.0. In this stage, Starway brand, led by Starway Eta Ursae Majoris, continues to make progress, pushing Chery Group to overtake in the global market, accelerating digital transformation, and accelerating strategic goals such as high-end brand and green brand.

The completion of Qingdao Super Smart Factory is a powerful guarantee to achieve the above goals. The factory covers four processes, namely stamping, welding, painting and final assembly, as well as a research and development center, test and test site, with a construction area of about 260,000 square meters. It will produce M3X platform series products including Starway Eta Ursae Majoris, and can produce a variety of conventional power and new energy passenger cars in a mixed line. It is estimated that the annual production capacity will be 200,000 units, and an entire vehicle will be rolled off the assembly line every 1.5 minutes on average, with an annual output value of 38 billion yuan and a supporting output value of 20 billion yuan. With the advantage of being close to the seaport, the products are not only supplied to the domestic market, but also sold to overseas markets.

According to reports, Xingtu Qingdao Super Smart Factory is the first super factory built and mass-produced among many similar factories. It takes digital intelligence, environmental protection, lean and efficient as its concept, applies C2M as its core and gives priority to customer experience in the automobile industry for the first time, establishes a large-scale, personalized and customized new production mode by introducing the Internet platform of Shanghai Cloud Industry, and adopts a very strict production quality management system. It is a 4.0 model factory that can benchmark the world’s leading intelligent manufacturing level.

Automobile manufacturing is divided into four major processes — — Stamping, welding, painting and assembly. However, the production methods of these four processes are different in different factories — — Some are mainly manual, and some are mainly machines. In fact, as long as people make mistakes, only by using machines as much as possible can we ensure the stability of quality.

In the stamping workshop, I only saw a few workers standing in front of the operation desk, staring at the contents on the display screen — — This production line is equipped with a fully digital management platform.

At the other end of the production line, there are many molds, which will be sent to the punching machine at any time for stamping according to the production demand.

Through the glass, you can see the working condition of the punching machine — — This production line is a 6600-ton full-automatic high-speed synchronous production line with 100% automation rate.

Just now, it was a roll of steel plate, and in a blink of an eye, it has become a body part.

The stamped parts are sent to the welding workshop for welding. This is the second step among the four major processes. In other words, the stamping parts are sent in at one end of the workshop, and a complete car shell is sent out at the other end, which is called body-in-white in the industry.

In the welding workshop, 350 AI robots can work at the same time. If you just catch up with your homework, you can enjoy the lively scene of yellow arms flying and sparks flying.

The workshop has a strong AI quality control system, which can realize intelligent linkage and high-density flexible assembly, and quickly switch to produce different models.

According to the introduction and chart, I understand that the automation of this workshop is quite high. The stamping parts are grabbed by the manipulator and sent to the workstation, and the welding robot immediately starts to work. After welding, the manipulator sends the finished parts to the transfer trolley.

Although it is fully automatic and highly reliable, there are still personnel to check and eliminate possible problems on the spot.

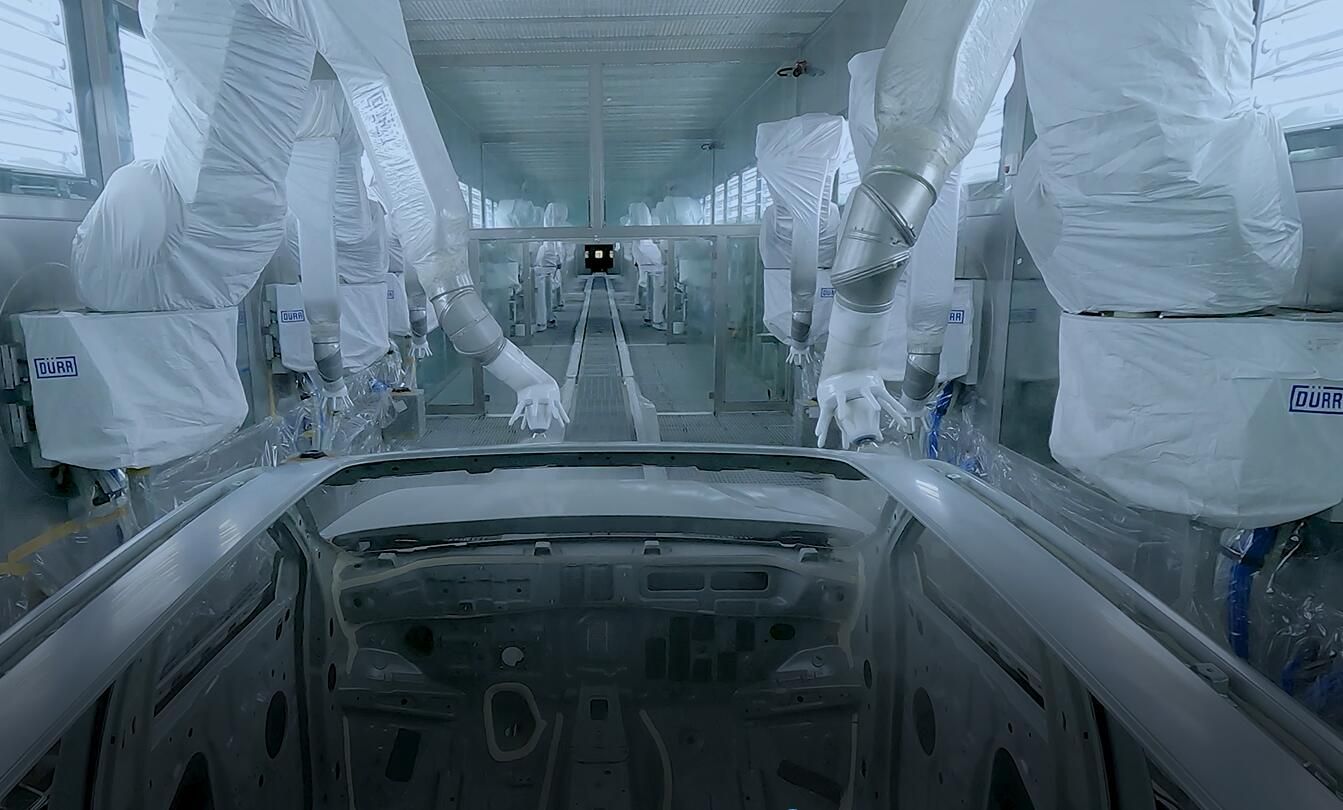

The third step among the four processes is painting. The welded body in white is painted here. According to reports, the painting workshop has the world’s leading "zero-carbon" intelligent technology, the ultimate energy-saving environmental protection technology, and the key processes are fully automatic.

The so-called environmental protection technology refers to coatings. Here, the compact water-based paint technology with energy saving and environmental protection is adopted, which is expected to reduce the gas demand by 22%.

All kinds of joints inside the car body, patches needed for noise reduction and vibration reduction, etc., are also completed by robots in the painting workshop.

The fourth step in the four major processes is final assembly, in which all parts, such as wiring harness, interior trim panel, instrument, seat, glass, engine, tire, etc., are assembled one by one in a fixed order, thus giving birth to a car that can run.

This assembly workshop has the world’s leading wisdom and high-precision technology, and has the advantages of short process, modularization and intelligence. Among them, the accuracy of the online appearance gap surface difference detection robot is as high as 0.02 mm.

Next to the assembly line, there is a branch line, which is specially used for power assembly. The 2.0T engine of Starway Eta Ursae Majoris, which has just appeared and started blind ordering, is delivered to the assembly line and loaded into the car body after the final assembly is completed here.

After everything is assembled, add gasoline, coolant, glass water, etc., and the car can run. After driving off the assembly line, it’s not over yet, followed by a lot of tedious inspections, such as braking, emission, and even simulating heavy rain to check the sealing condition of the car body.

Under the strong light, workers need to observe the car body carefully. If they find defects, they have to "enter another book" and wait for further treatment.

Through the above simple description, we can see that Starway Eta Ursae Majoris, as the first strategic model of Starway Brand 2.0, has been rigorously polished in this super-intelligent factory, which makes it have excellent product quality, quality reliability and consistency of "ten thousand cars are the same".

Environmental protection in the manufacturing process is something that consumers usually don’t pay much attention to, but in fact, carbon neutrality has become a global consensus. Starway’s super smart factory fully responds to the "double carbon" strategy and minimizes the "carbon footprint" in the whole life cycle. For example, using reclaimed water reuse and rainwater reuse technology to ensure the full recycling of water resources can save 180,000 tons of water every year. For another example, high-density photovoltaic panels are used to generate electricity in a large area, and the remaining electricity can also be connected to the Internet. Combined with energy storage, a smart microgrid is formed, with an average annual power generation of 14 million kWh and a reduction of 110,000 tons of carbon emissions.

In addition, the factory also adopts the world’s leading coating technology, waste heat utilization and condensed water recovery technology, reducing gas by 852,000 cubic meters every year, which can meet the most stringent environmental protection standards in the world, including those exported to Europe. Coupled with Qingdao’s proximity to the sea, it can give play to the advantages of the "Belt and Road" bridgehead and the SCO platform. Green and low carbon has become one of the core competitiveness of Xingtu Qingdao Super Smart Factory.

More: Starway Eta Ursae Majoris is the world premiere. If you use a computer or tablet to read, click on the picture below to enter directly.

On December 27th, 2022, Xingtu brand was named "Exploration • With the theme of "Future", Eta Ursae Majoris’s world debut ceremony was held in Qingdao Super Smart Factory, and blind booking was started at the same time, with a blind booking price of 17– 220,000 yuan. Eta Ursae Majoris is a smart, luxurious and flagship model with 400,000-class quality, which breaks the sensory boundary of consumers and fully empowers the high-end and trendy travel experience of urban light and middle-class people.

During the blind subscription period, the first batch of consumers participated through the official WeChat applet of Starway, and they can enjoy five gift packages by paying 99 yuan’s subscription:

Gift package 1: draw 100% of the prizes, with the face value of 100 yuan e-commerce shopping card, or exclusive clothing on Star Road — — High-quality jacket worth 1000 yuan.

Gift package 2: car purchase vouchers, 2,000 yuan can reach 5,000 yuan.

Gift package 3: Buy a car and enjoy the first batch of priority delivery rights.

Gift package 4: after buying a car, send [Hi Star Road] app points of 20000.

Gift package 5: the right to visit Qingdao Super Smart Factory on Xingtu.